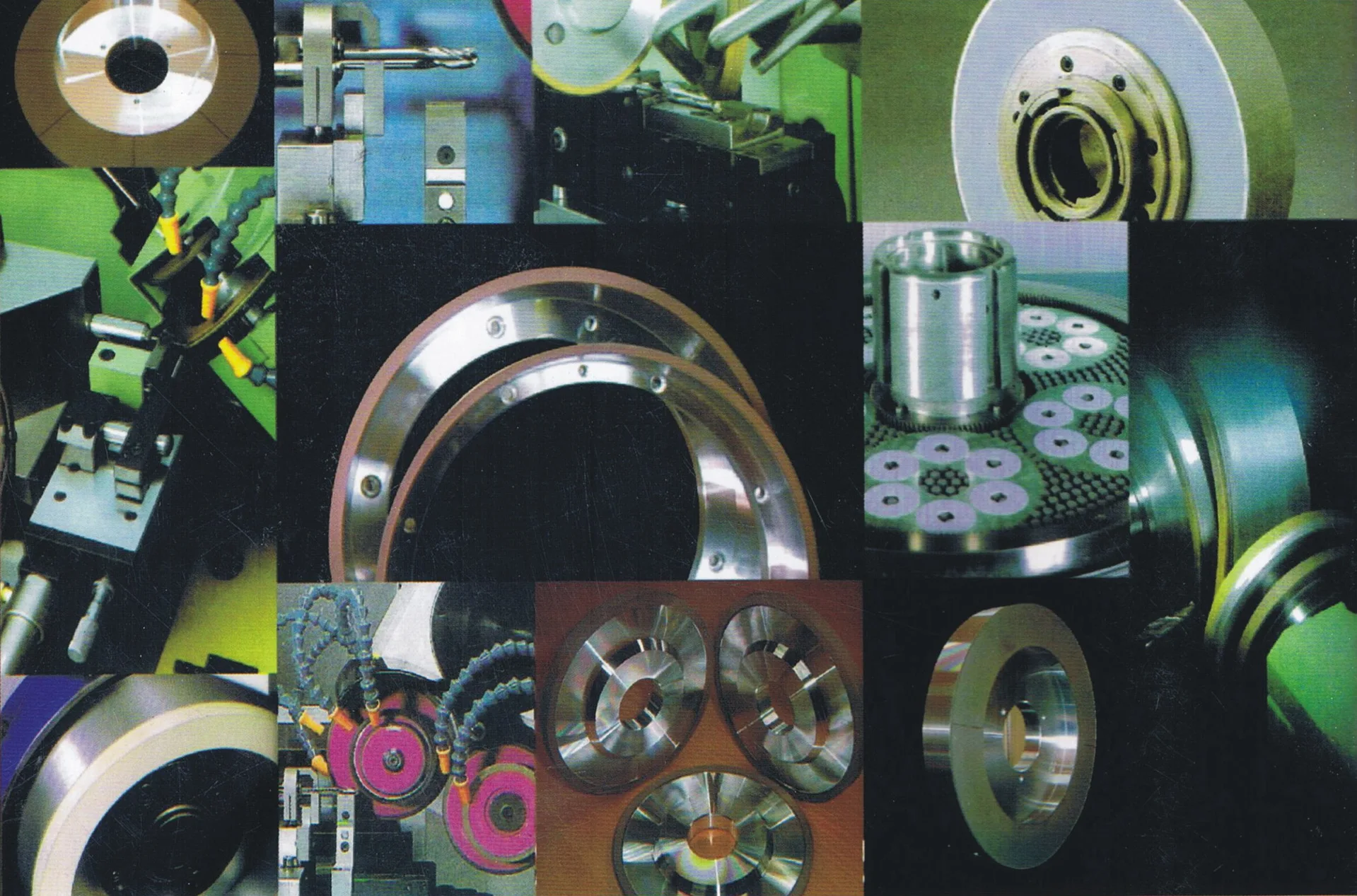

JJSTONE features: material selection performance excellent diamond or cubic boron nitride with imported high temperature resin with professional technology, mainly used in hard alloy tools, moulds, precision ceramic, PCD, PCBN, stone, magnets, semiconductor, glass, jewelry and other industries, drastically solved the difficult problem of customers, reduces the customer grinding cost, improve the machining precision and machining efficiency of the clients. All kinds of special specifications of products, we can be customized for the design.

The characteristics of electroplated bonded grinding wheel are that the proportion of sand and binder is particularly high, and the grinding grain is also particularly exposed, so the grinding efficiency is very high.

How to order grinding wheel

1, Choose the right binder:

A,resin bonded grinding wheel : High bonding strength, elastic to a certain extent, poor heat resistance, coolant is not easy to enter. B,vitrified bonded grinding wheel: The porosity is high, the coolant is easy to enter, and the dressing is easy.

C,electroplated bonded grinding wheel: There are many sand grains and high teeth exposure, so grinding efficiency is high.

D,metal bonded grinding wheel: Sand high bond strength, very wear - resistant, difficult to repair.

2,Choose the right abrasive:

A,Dianmond:It is the abrasive with the highest hardness. However, during the processing of iron workpiece, due to the heat generated by grinding, iron and diamond will react and destroy the diamond, so it is not suitable for the processing of iron workpiece. B,CBN: Second only to diamond in hardness, suitable for grinding all kinds of steel above HRC40.

3,Choose the right abrasive grit size

4,Select the shape and size of the grinding wheel

Since the establishment of JJSTONE in 2014, we have been focusing on the field of diamond grinding wheel manufacturing. Today, JJSTONE is a very competitive product in China, which is widely recognized, and it keeps expanding its business field with the manufacturing technology and professional knowledge of diamond grinding wheel. JJSTONE has a wealth of knowledge in industrial diamond tools, and it is a principle to provide continuous technical support to users. Our experts always listen to users and try their best to meet their needs. Nanchang JJSTONE technology co., LTD, specializing in the production of resin, ceramic, metal, electroplating diamond (SDC) and cubic boron nitride (CBN) grinding wheel, the company has automatic hot pressing machine, CNC machining center, CNC lathe, dynamic balancing instrument, universal tool grinder, universal precision cylindrical grinding machine, high-speed rotary machine, laser engraving machine, such as professional production and testing equipment, external cylindrical grinding wheel maximum diameter is 700 mm, maximum end face grinding wheel diameter is 1200 mm. Purchase imported high quality raw materials, committed to provide customers with high quality grinding wheels of all types, and work with customers to solve various grinding technical problems.

We mainly customize grinding wheels according to customers' requirements, so please be sure to communicate with the sales staff before placing an order for grinding wheels.